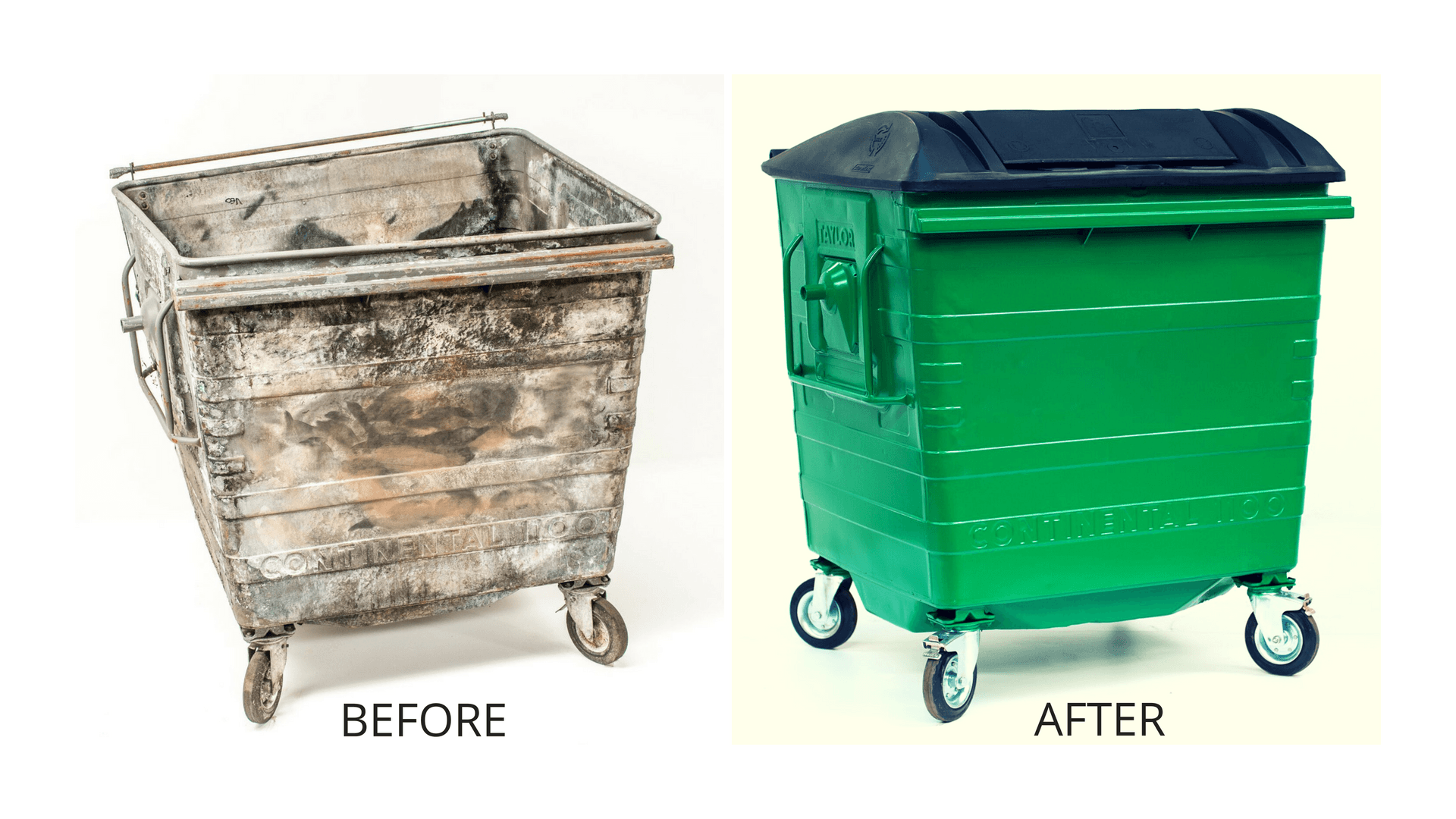

FACTORY REPAIR AND REFURBISHMENT

Our Container Refurbishment Plant in Cheshire is the largest of its kind in the UK utilising state of the art equipment

(shot blast booths, spray booths, heavy fabrication bays) to ensure that all stages of the container refurbishment and testing process are carried out to the highest achievable safety, quality and environmental standards, thereby ensuring complete customer satisfaction.

UK Container Maintenance offer a complete repair & refurbishment programme to all makes and models of waste and recycling containers from wheeled containers to REL's, FEL's, Rollonoff's and Packers, giving our Customers a fully inclusive service, including collection and delivery of containers to and from depots throughout the country.

Large stocks of containers can be easily accommodated within its 5 acre,

80,000 sq. ft. site. The Site is fully secured; insured and monitored by CCTV.

These security measures ensure that UKCM are able to react promptly to our customer’s requests for delivery, by our dedicated fleet, to support their roll out/in or operational requirements.

UKCM also boasts its own in-house testing facility which ensures all repairs and modifications to all wheeled containers are carried out in line with industry guidelines BS EN840 parts 1-6 .

The dedicated facility verifies that any work carried out is fundamentally sound and passes original testing requirements giving peace of mind that repairs are carried out to the highest achievable standards.

And with a massive 95% refurbishment percentage our business is to repair, refurbish & deliver these containers back to work. However in circumstances where containers & spares are beyond economical repair or deemed as scrap, these containers and their parts are cannibalised, remanufactured or recycled back wherever possible for the purpose of fulfilling UKCM's circular economy and recycling aims.

Slide title

Write your caption hereButton

These containers will have their serial numbers documented. If they come in without serial numbers, new numbers will be issued and welded onto the containers.

UKCM can track all work that has been carried out on the containers so we can create a full audit trail of the containers we will be refurbishing for you. UKCM can also make containers tag ready and fit RFID tagging if required.

The UKCM site in Cheshire is fully secured, insured and is monitored by CCTV, so we can hold large stocks of your containers securely awaiting delivery out to the depots as and when required. In addition to this we can support your roll outs and roll ins with our dedicated fleet.

24 YEARS

WORKING WITH INDUSTRY. LOCAL AUTHORITIES AND BUSINESSES OF ALL SIZES ACROSS THE UK

£271 MILLION

SAVED BY REFURBISHING OUR CUSTOMERS CONTAINERS

1.8 MILLION

CONTAINERS REPAIRED, REFURBISHED AND REUSED

GET IN TOUCH

25 Road One,

Winsford

Cheshire

United Kingdom

CW7 3QP

SIGN UP FOR OUR NEWSLETTER

Thank you!

Please try again later